BERFIN EVRIM

Architecture & Design

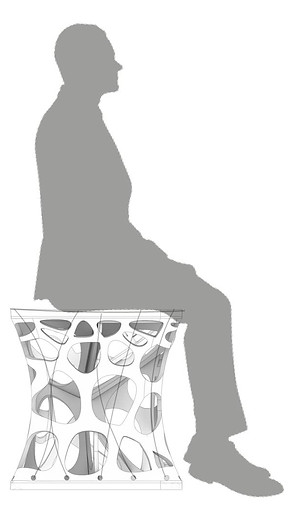

Bone Stool: Weaving and 3D Printing

This thesis presents research that combines weaving and 3D printing to fabricate a textile that will be used for supporting a person on a stool or chair. This textile uses carbon-reinforced polymers and jute fibers that are stiffened by thermoplastic elastomer (TPE) to achieve adequate resistance with lightweight material. The use of TPE offers a biodegradable option as a stiffener in the textile. 3D printing different geometric toolpaths allow for variable rigidity in the fabric. The goal of this research is to design a chair of 20 by 20 inches that withstands loads of a 250 pounds person, using a physical and digital model of 5 by 5 inches.

Contributions of this research include several geometric tool paths affecting the stiffness of the textile in combination with the weaving pattern and weaving materials. These toolpaths also include geometry inspired by cow bone structure. Besides, a digital tool was developed coded in Grasshopper that allows for parametric modeling of textiles (stiffness, geometry, etc.). These textiles can then be loaded in this digital tool, and their behavior simulated to understand the maximum strengths of each textile design. This approach prevents material waste and allows designers to generate fabrics for possible architectural applications in different loading conditions.

Fall 2019-Spring 2020

Bone Analysis

SEM Images of Trabecular Cow Femur Bone

Different Weaving Patterns and Carbon Fiber to Jute Fiber Ratio

Deformation in Diagonal Direction

3D Printing on Jute Fabric

Solution for Fabric Deformation and Distortion

Bone Stool Views: TOP, BOTTOM, SECTION AND FRONT

Fabric Structure Elements

Orthogonal Layered Double Fabric

Textile and Frame Connection- Bone Stool

Karamba 3D-Structural Testing: Displacement

Tension and Compression Forces & Force Lines